Commercial kitchen equipment is the backbone of every restaurant and frequent use of this equipment may lead to unexpected breakdowns or failures. Preventative maintenance is the best way to prevent equipment downtime and reduce costly repair costs due to maintenance neglect.

We've seen almost every VCM-related issue and helped thousands of customers worldwide solve them. We'd like to share a few common operational mistakes along with preventative maintenance tips:

#1: Check the Rotation

It sounds simple, but it's a mistake that is often overlooked. All VCMs are designed to run in the clockwise direction only. Running the mixer counter-clockwise will result in poor performance in dough forming and damage to the knife cutter blades.

If you discover that your mixer is NOT running clockwise a simple change to the plug/outlet wiring is needed. Please consult an electrician to help you make this change.

#2: Check the Cutter Blade Configuration

Another common mistake we see is cutter blades installed upside down or backwards. It's an easy mistake to make so we made a new video to help you install them correctly. Watch our installation video here.

#3: Check the Motor Fan Screen

The electric motor relies on air flow to keep cool. Running a mixer with a clogged screen may result in overheating and damage to the motor. To clean this screen, simply tilt the machine on its side and use a wire brush to remove debris.

#4: Check the Seals

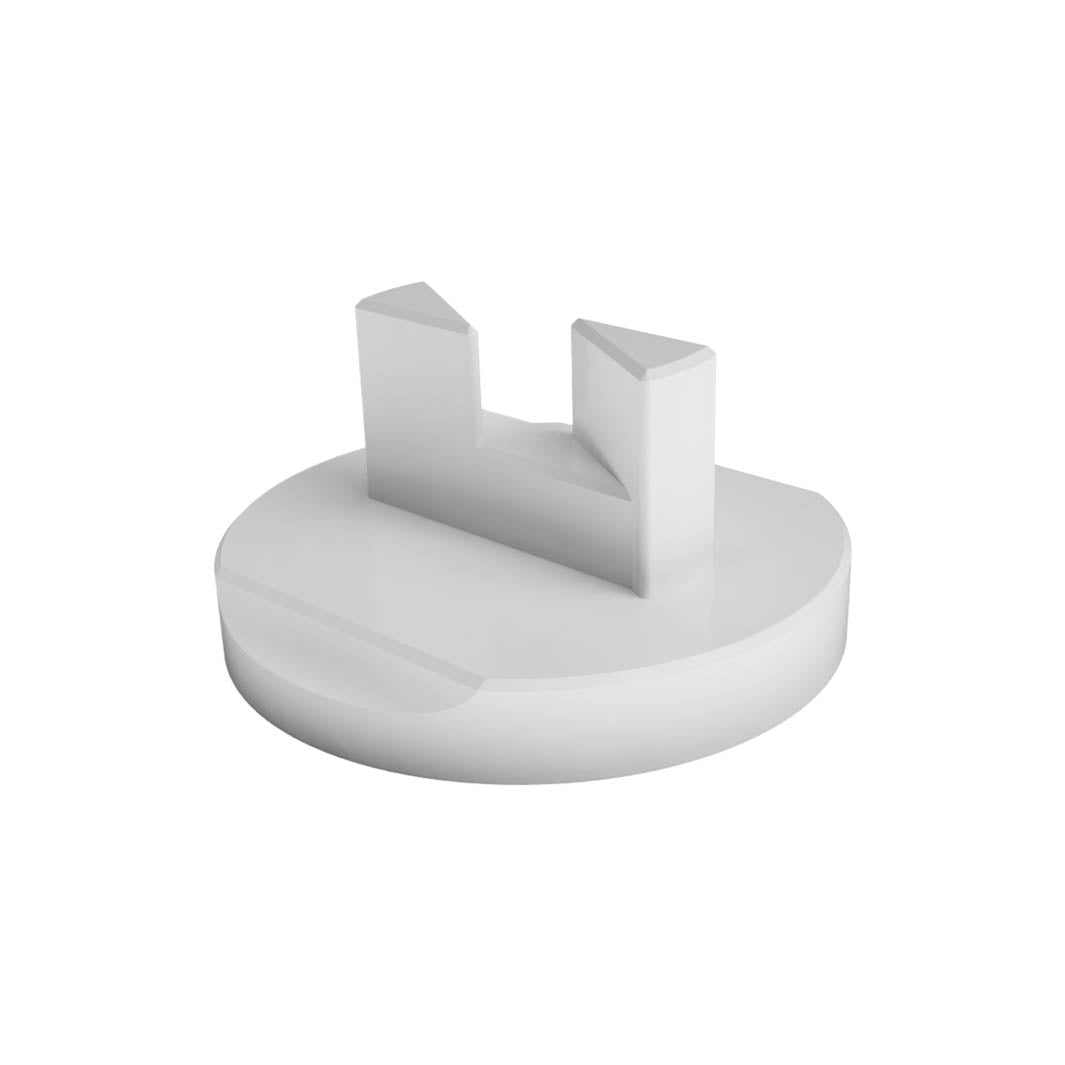

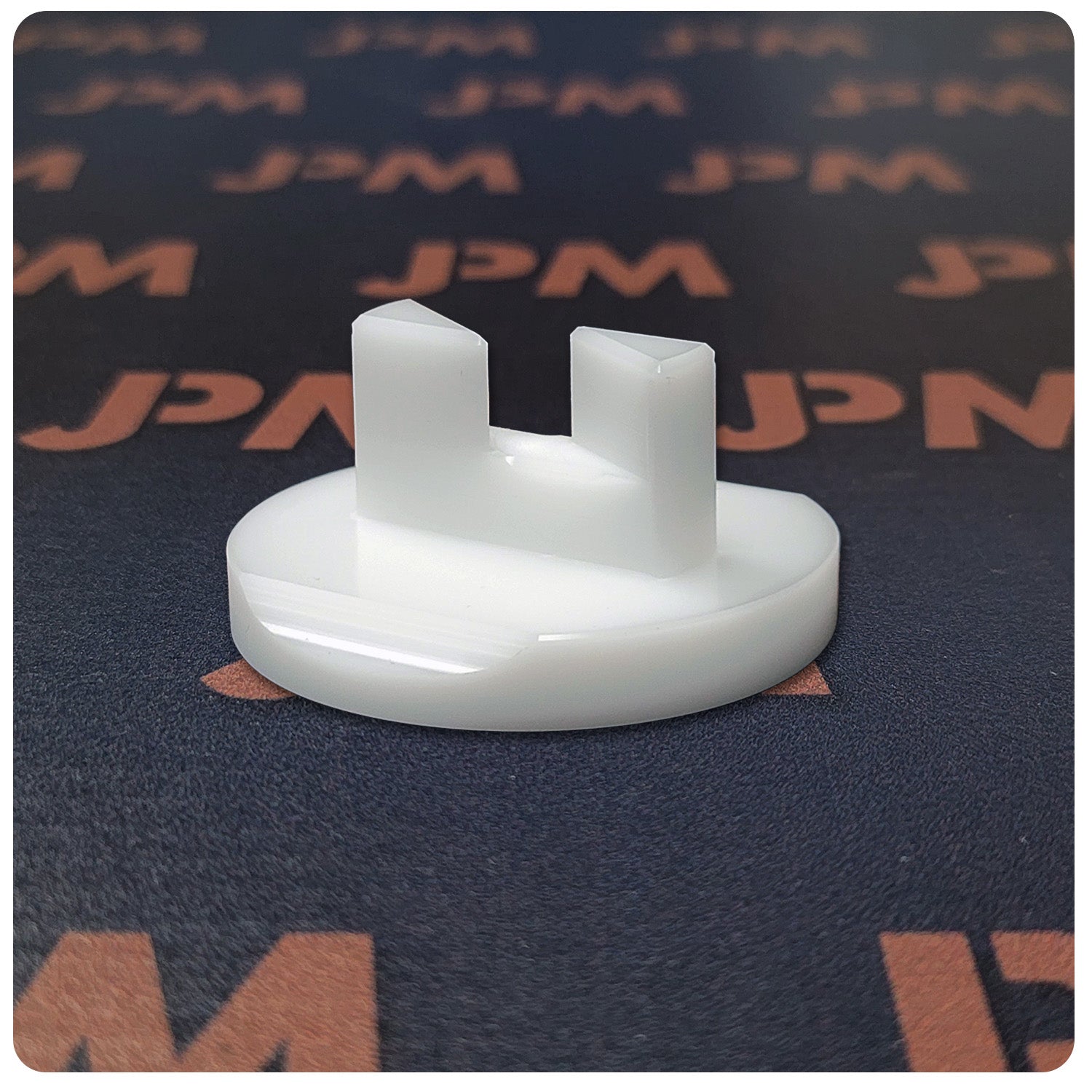

Bowl Seal and Shaft Sleeve (Pictured left): The bowl seal and shaft sleeve work together to keep liquids from damaging the upper bearing and the electric motor. It is important to regularly inspect your bowl seal and shaft sleeve and re-lubricate once every two weeks. A good bowl seal and shaft sleeve will not allow liquid to pass through the bowl. See the maintenance kit here.

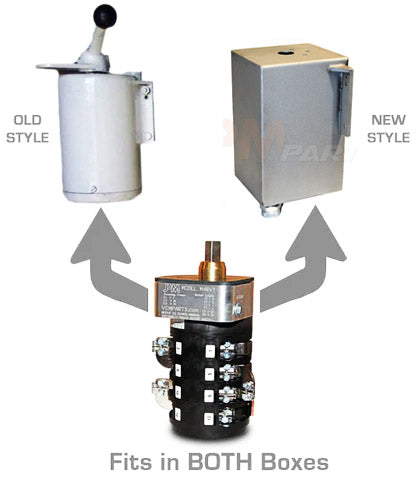

Drum Switch Handle Seal (Pictured right): Be sure to inspect that your drum switch handle is properly sealed. Without this seal, liquids can enter the drum switch housing cause damage. See the drum switch seal here.

#5: Check the Bearings

Liquids are the number one cause for bearing damage and can be prevented with a good bowl seal. The easiest way to check the quality of the bearings is by spinning the rotor shaft by hand. A good set of bearings will not make noise and will spin freely by hand. If you feel any resistance, scratching or growling then you may need to replace the bearings.

Also grab the rotor shaft from the top threads and push it back and forth. A good set of bearings will not allow any slop or movement. If you do have movement then we highly recommend replacing the bearings. Not only will this damage your bowl seal (from lateral movement), it can lead to motor damage. If severe enough, the movement allows the rotor to rub up against the stator (motor).

Here is a link to our rebuild kit (includes new bearings)