IMPORTANT!

DISCONNECT POWER

before working on any equipment

ELECTRICAL EQUIPMENT SHOULD BE INSTALLED, OPERATED, SERVICED, AND

MAINTAINED ONLY BY QUALIFIED PERSONNEL. NO RESPONSILIBITY IS

ASSUMED BY JPM PARTS FOR ANY CONSEQUENCES

ARISING OUT OF THE USE OF THIS MATERIAL.

USE A VOLTAGE METER TO CONFIRM POWER IS OFF!

let's get back to...

The Basics

Before troubleshooting we must verify that our incoming power is confirmed GOOD and HEALTHY. We have seen many scenarios is which the power source was the cause of the problem.

We will also cover checking all of our power connection points from the breaker to the mixer.

Why Consistent Power Matters

For your mixer to start and run correctly, all three power lines must be present and consistent. If one of the three phases is weak, missing, or incorrectly wired, the motor might:

- Fail to start

- Overheat

- Trip safety overloads

- Make a loud humming noise and draw excess current

This power must remain consistent from the breaker to the motor.

WHAT IS 3-PHASE POWER?

The VCM 44 runs on 3-phase power, which means the machine receives electricity through three “hot” wires— labeled L1, L2, and L3. The fourth wire is ground.

Unlike a standard single-phase system (like what you have at home), 3-phase power delivers a more stable, balanced flow of electricity that keeps heavy-duty motors running efficiently.

1. CHECK THE INCOMING POWER

Find the breaker box and have an electrian check the incoming power. There are three wires going into this 3-phase breaker.

Using a voltage meter, one could confirm that the incoming power is correct by checking:

Voltage at L1 to L2

Voltage at L2 to L3

Voltage at L1 to L3

Do not check the line wires to ground, test power across each pair separately.

Each pair should match the voltage on the mixer's motor tag. You should not see more than 1% - 3% voltage deviation across the legs.

If one leg is missing or lower than expected, the issue might be with your building’s power supply—not the mixer.

It's crucial we check the power at the source. The VCM 44 runs on a 30 AMP breaker and is typically on a 208v - 220v service.

INCLUDING:

FAQs for the This Section:

POWER CONFIRMED GOOD?

Don't Skip the Simple Stuff

2. Check the Physical Connections

Even with perfect incoming power, your machine won’t run if the internal wire connections are loose, corroded, or damaged.

Over time, vibration, heat, or even previous service work can cause connections to:

- Loosen

- Oxidize or corrode

- Break at the terminal or under insulation

A single loose wire can result in:

- Intermittent power

- No operation at all

- Arcing or overheating, which can damage terminals or trip breakers

WHAT TO LOOK FOR:

- Tug gently on each wire: is it snug and secure in its terminal?

- Check for burn marks, discoloration, or melted insulation

- Look for broken strands at the terminal ends

- Ensure the ground wire is connected securely to the frame

⚠️ PRO TIP

Always check both ends of the wire: at the terminal block and where it connects to components like the contactor, motor leads, or safety switches.

FAQ for This Section:

Common Problems & Suggestions

All advice from now on is assuming that the incoming power is GOOD and HEALTHY

NOTERemember that any information or advice shared here is for general knowledge and educational purposes only. It should not be considered a substitute for personalized professional advice from a qualified expert. Always consult with a licensed professional before making decisions or taking action based on information you find below.

1Motor makes a loud noise or blows the breaker

2No timer display, power loss

3Timer display working, but does not start

4Mixer randomly shuts off during operation

5Blind stopper damage

6Bowl leaking

7Closed lid has gaps or mis-alignment

8The tilt is not locking correctly

9Lid spring not working

STILL NEED HELP?

Our Contact Information is Found Below

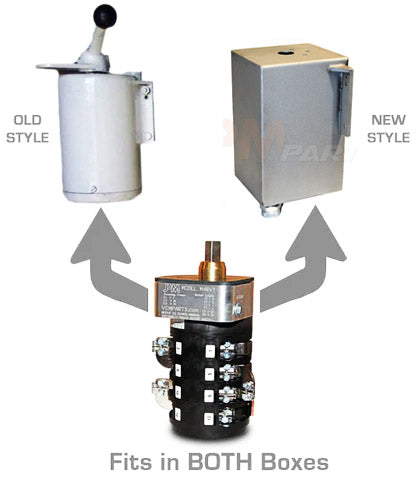

An industrial-grade protective housing designed for harsh commercial kitchen environments.

- Available for Autonics/JPM Timer & Eagle Signal Brand

- Material construction resistance against grease and oils

- 16-gauge marine vinyl splash shield – replaceable and durable

- Corrosion-resistant stainless hardware

- Embedded brass thread inserts for long-term integrity

- Custom rubber gasket included

- Redesigned brackets for increased clearance and compatibility (Autonics Timer Only)

JPM TimerGuard

Protect Electronics

Learn MoreBuilt from high-performance materials, with a water-resistant marine vinyl shield, stainless hardware, and embedded brass inserts for long-term durability.